Advantages of a flexible impeller pump

Cost effective: Is an economical alternative to many other pump types.

Gentle: Carefully can handle fluids containing hard and soft solids, up to 3/4"size.

Viscosity: Flexible impellers handle from low and high viscosity fluids, gels and pastes up to 20,000 CP according to the RPM.

Self-priming: Are capable to lift from a depth up to 15 feet. (Water)

CIP return: Can handle air and gas contained products which cannot be pumped by general centrifugal pumps.

Reversible operation: The pump can work in both directions.

Maintenance: Easily dis-assembled and clean.

*If you have a lifting application contact us for more information: info@tptstainless.com

Flow and pressure

| 1 HP up to 13 GPM @ 30 PSI |

| 2 HP up to 35 GPM @ 30 PSI |

| 3 HP up to 44 GPM @ 30 PSI |

This information is provided for reference purposes only. To find out which pump is best for your application, please fill out our pump application data sheet

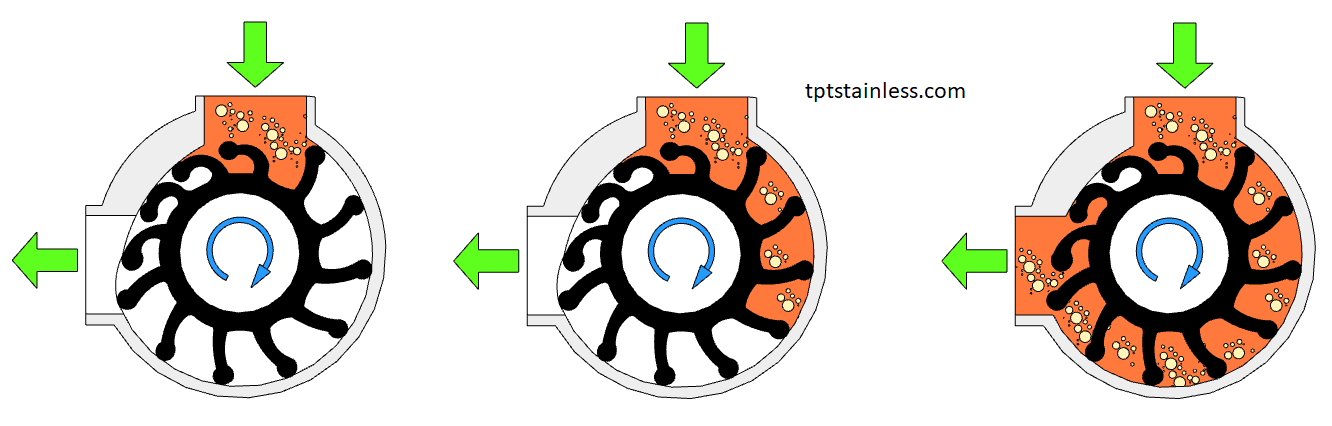

Operating principle

Due to the eccentric shape of the pump housing, a vacuum is created in the suction side that

enlarges the volume between the blades and this causes the product suction.

The rotor is spinning and the product is carried from the suction side to the discharge outlet.

Due to the eccentric shape of the pump housing, at the discharge side, the blades bend,

reducing the volume between them and causing the discharge of the product

Viscosity tests

Watch the Videos Below

How often should the impeller be replaced?

Flexible Impellers can last around 3,000 to 4,000 hours or 2 to 3 years at ambient temperature @ 1,450 rpm

Impellers can be damaged by debris, incompatible chemicals, and especially by running dry.

Flexible impeller pumps work best when run regularly.

GASKET PROPERTIES

Static Seal: A static seal is located in a groove and has no movement.

Examples: O-rings and Tri-Clamp® fittings gaskets

Dynamic seal: A dynamic seal is exposed to movement.

Examples: Butterfly valve gaskets

Static Seal Temperatures

| GASKET PROPERTIES | EPDM | VITON |

|---|---|---|

| Heat resistant | Excellent (275°F) | Excellent (400°F) |

| Cold resistant | Good-Excellent (-20°F) | Good-Excellent (-30°F) |

| Steam | Good | Excellent |

| Abrasion resistant | Good-Excellent | Good |

| Alkali | Good | Poor-Good |

| Acid resistance | Good-Excellent | Good |

| Vegetable oil | Good | Excellent |

| Petroleum oil | Poor | Excellent |

| Oxonia | Good-Excellent | Excellent |

| Ozone | Good-Excellent | Excellent |

Centrifugal pumps do not apply for free shipping

Please call for shipping cost