Product recovery

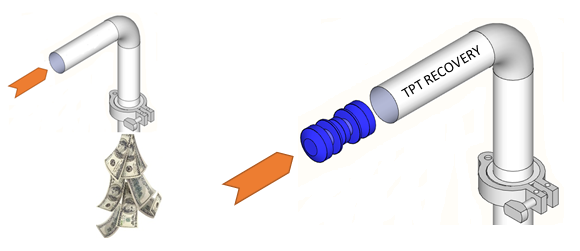

Don't Throw Money Down the Drain

- INCREASE YIELDS

- REDUCE CHANGEOVER BETWEEN PRODUCTS

- REDUCE CIP COST

- REDUCE WASTE WATER LOAD

What is a "PIG" recovery system.

The Pig is a flexible projectile, driven by compressed air, water or CIP cleaning solutions.

The Pig cleans the pipeline enabling maximum product recovery after production or changeovers.

process energy savings

Process optimization to minimize energy use in food processing:

Air compressed: Compressed air is often wrongly assumed to be cheap or even a ’free’ source of power. Numerous independent studies confirm that industry wastes around 30% of the compressed air it generates.

Steam: When steam traps leak or fail, it can be extremely costly in terms of product quality, safety and energy loss.

Leak detection using Ultrasound:

Ultrasound leak detection covers a wide range of leaks: pressure or vacuum and any gas. Sound dependent, ultrasound instruments detect turbulent flow produced as the fluid (liquid or gas) moves from the high-pressure side to the low-pressure side of a leak.

pumping systems

Pumps are often over-sized or operate not at their ideal point of operation.

Product recovery

Reducing water usage in food and beverage processing:

Water is an essential input for the food and beverage industry

Opportunity Areas:

- Water is used for cleaning in place

- Cleaning out of place

- Heat exchanges

- Pasteurizers

- Washers : Bottle washer, product washer like (Corn, fruits and vegetables)

- Manual cleaning, sanitation and miscellaneous utility demands.

rcm, rca, p&s comissioning

We are highly qualified and trained to join our clients in the implementation and commissioning of the different maintenance programs such as RCM, RCA and maintenance planning.

Commissioning of RCM

The Reliability Centered Maintenance is a methodology for developing highly effective maintenance plans, which through a systematic review of possible failures with different teams of subject matter experts, define the most relevant tasks for future prevention or mitigation. The Commissioning Process consists of:

- Enroll the company personnel in the maintenance plan development

- Load maintenance (CMMS) Software plans derived from RCM analysis

- OT implementation with technical crafts

- Work order closure procedures

Commissioning of RCA

We recommend a multi-functional team of people participate in the root cause investigation process. IME provides a support role as needed to ensure that the investigation continues to move forward, appropriate evidence is collected, cause-and-effect relationships are being captured to the appropriate level of detail, solutions are connected back to specific improvements in work process and the entire investigation is being documented efficiently and clearly. This coaching (support) role ensures a complete investigation by keeping the group consistent and moving in the direction of completion (solutions).

Commissioning Maintenance Planning

This methodology seeks to implement best practices in the area of planning and scheduling maintenance work, greater staff productivity, optimize workloads, greater availability of equipment and higher quality and more cost effective maintenance.

In the Start up we will guide the staff to implement the cycle of the 5 planning stages, these stages are:

- Post-Maintenance Day Staging

- Planning & Scheduling Staging

- Stockrooms Staging

- Pre-Maintenance day Staging

- Maintenance day Staging