Protecting Products and Equipment from Particulates

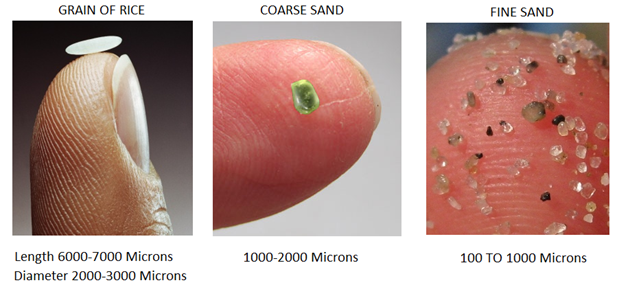

In-line Coarse Strainer

Side Entry Coarse Strainer

In-line Fine and Medium Strainer

with mesh over screen

Coarse Sanitary Strainers

Fine and Medium Strainers

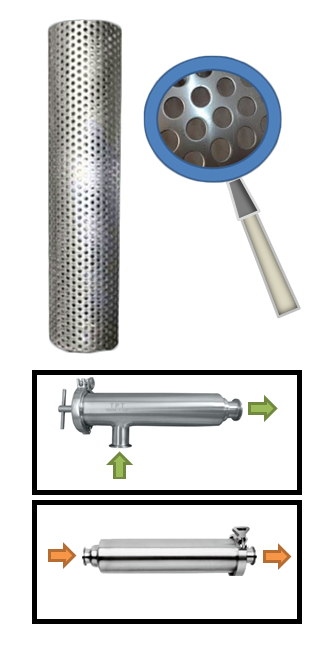

Single perforated screen with round holes for straining large particles.

"Without mesh over screen"

Backup tube and wire mesh over-screen for fine and medium particles.

"With mesh over screen"

Related products

GENERAL INFORMATION

How do I know when the strainer needs to be cleaned out?

Installing a pressure gauge before and after the strainer .

When the differential pressure reaches 8-10 psi is time to clean the strainer element (back-up tube or wire mesh over screen)

What happens when you don't properly clean your strainer element?

Without a properly cleaning, the strainers will eventually accumulate solids to the point that they become more restrictive to the flow and this causes an increase in differential pressure and the element (back-up tube or wire mesh over screen) may collapse.

Difference between a filter and a strainer:

The basic difference between a strainer and filter is the degree of filtration.

Both are devices designed to remove particles from a liquid or gas. Strainers are intended to remove larger particles, and filters remove much smaller particles, which you normally can’t see.

Strainers are generally installed to protect your products or process equipment like control valves, pumps, flow meters, homogenizers, etc.

Strainer selection criteria:

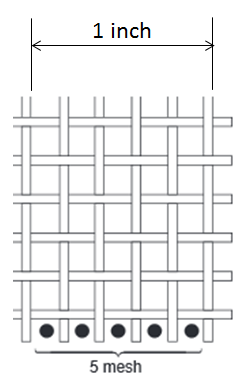

• Particle retention (Mesh size to be used in the strainer)

• Amount of free open area

• Fluid properties (Viscosity, flow rate, etc.)

• Location of the strainer

• Pressure drop allowance

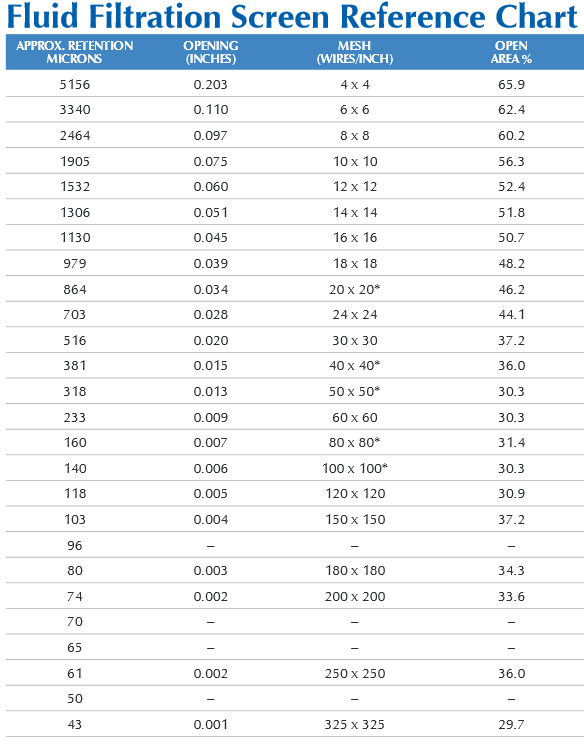

What is the mesh size?

It is the number of wires per inch in both a vertical and horizontal direction.

What does "free open area" mean?

Strainers can’t be selected according to the pipeline size!

The term "Open Area Ratio" or "Open Area to Pipe Area" is a measure of relative particle-holding capacity and is usually between 2 to 4 times the inlet pipe area (cross sectional area of the pipe). Anything less may cause excessive pressure drop and short filtration cycle time.

What’s effective filtration area?

It is the total area of the filter element that is exposed to the fluid flow.

The larger the filter area, the longer filtration cycle time.

What is the effect of adding the mesh over the screen to the strainer element?

The mesh over screen reduces the effective opening of the strainer backup tube.